Although machine safety circuits are primarily designed to protect employees from harm, they can also deliver higher profitability. By integrating inherent safety features into machine design, OEMs can elevate productivity and unlock fully engineered solutions. Clement Pucher, Manager of the European Working Group Safety Technology at SMC Europe considers the link between machine safety and profitability.

Reducing Accident Risks

Safe and advanced machine design does more than enhance operational control; it directly contributes to productivity and competitive advantage. High safety standards reduce the risk of workplace accidents, which carry both direct and indirect costs.

Direct costs include insurance claims, production losses from employee absence, the expense of hiring temporary staff, and healthcare fees. Indirect costs, often overlooked, involve the productive time lost due to accidents and the downtime needed for operational recovery or machine adjustments.

These financial burdens erode profitability, yet they are avoidable. By prioritising machine safety and profitability, OEMs can sidestep these costs while benefiting from enhanced efficiency.

Reducing Downtime Through Optimised Machine Safety

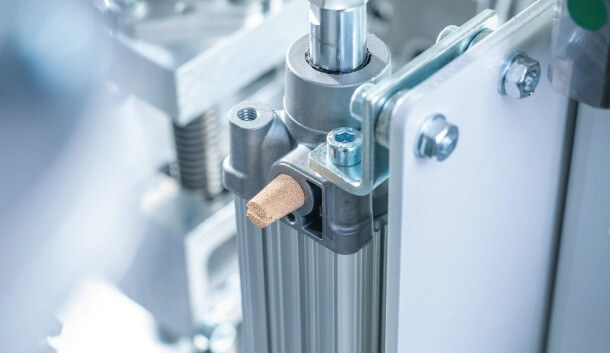

Well-designed machine safety circuits not only minimise unplanned downtime but also reduce short, planned stoppages. For example, effective safety measures ensure that setup operations, maintenance, repairs, or cleaning can be conducted quickly and without compromising safety. This approach eliminates the need for measures like cutting off the compressed air supply during short pauses, which can reduce downtimes and improve productivity by 5-7%.

Beyond uptime, safety measures can enhance productivity through easier troubleshooting, reduced scrap, and higher operator efficiency. These improvements streamline operations, maximising the return on investment in safety technology.

Addressing Global Safety Trends

Workplace safety requirements are becoming increasingly stringent worldwide. In addition to protecting employees from injury, companies face rising public sensitivity to working conditions, stricter trade agreements, and evolving economic laws. At a time when product complexity is rising, and technical skills are declining, OEMs must adapt by leveraging technical partnerships to navigate this challenging landscape.

A Holistic Approach to Safety

SMC recognises that modern machine development requires more than delivering components. Their approach includes holistic support that integrates functional safety, regulatory compliance, and technical design. By partnering with OEMs throughout the machine lifecycle, we offer tailored solutions that transform technical challenges into strategic opportunities.

This comprehensive support begins with navigating complex safety regulations and standards. From risk assessments to safety function analyses, we provide expert guidance to ensure machines meet stringent requirements. Their assistance extends to developing safety circuit diagrams, interpreting safety data such as Mean Time to Failure (MTTF), and providing TÜV-verified circuit solutions through tools like SISTEMA and the PneuSAFE online platform.

Bridging the Skills Gap

To address the growing skills gap, together with SMC, we offer extensive training and support services. By assisting OEMs with tasks like system analysis and component selection, SMC and BPX empower teams to build their technical capabilities. This collaboration ensures that safety solutions are not only effective but also tailored to the unique needs of each machine.

Transforming Safety into Profitability

SMC’s role as a technology partner goes beyond supplying products, to one of machine safety and profitability. By delivering innovative, reliable solutions, they and we help OEMs enhance both machine safety and economic performance. This partnership fosters safer, more efficient operations while driving profitability in an increasingly complex engineering landscape.

At BPX, we understand machine safety. As a SMC Platinum Integrator Sales Partner with 60 years of experience and a nationwide branch network with stock local to you, we have adopted a customer-centric approach to our factory automation and industrial control business. Most important of all, we can help you make a difference.

Should you be an OEM or machine builder, and wish to discuss your particular machine safety requirement, please do not hesitate to complete and submit the contact form below and one of our SMC specialists will be in touch with you at the earliest opportunity.