According to Schneider Electric, many industries, are reaching a productivity ceiling, but on-machine data processing using industrial edge computing offers a possible solution.

In many businesses productivity has plateaued as traditional technologies limit how workers perform their jobs. Addressing these limits requires new tools and a collaborative approach to work. The search is on for new ways to improve industrial productivity.

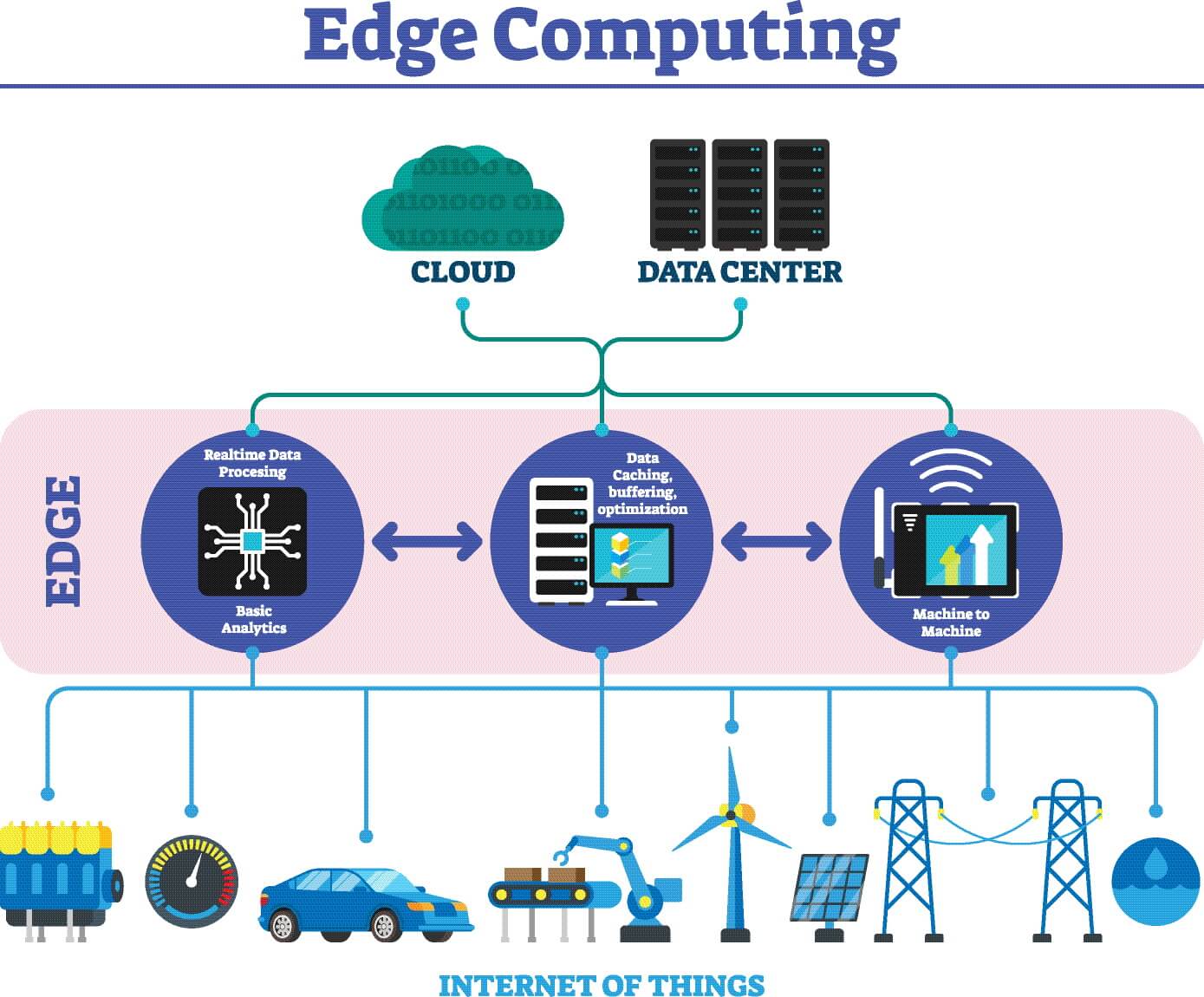

IoT technologies focus on capturing and analysing industrial machine operational and production data. Analysis of this new found information enables users to improve their productivity. It uses cloud and industrial edge computing as the basis for faster local decision making. Companies can also exploit this internal data to improve their upstream and downstream supply chains.

Business Analytics

Predictive analytics from IIoT devices and sensors on the shopfloor play an important part in smart manufacturing. They do this by tracking a range of relevant variables from the machine or process, including temperature and humidity, power usage, drive characteristics, vibration. By consistently comparing the data allows them to make accurate predictions of when and how machine components will start to fail. It improves Overall Equipment Effectiveness (OEE) which impacts availability, quality, and efficiency. Importantly, it reduces costs and losses due to unplanned downtime.

Another application of industrial edge computing uses video analytics for improving product processing. The cameras control the sorting and automatic rejection of products on high-speed conveyors. They also support the processing of rejected products according to different criteria.

Business analytics provide producers with improvements to real-time productivity and output. Better processing reduces costs and improves quality, allowing producers to address changing consumer demands. They also enable them to negotiate with their supply chain from a position of strength.

Industrial Edge Computing

How companies deploy and combine these technologies into “hybrid” (cloud + edge) environments depends upon many factors. For example, the location of the industrial facility and the impact of local regulations. Also, the criticality of the work and latency when acquiring and analysing data. Finally, the degree of security required, and the short and long-term needs of the business.

Besides their deep expertise in process automation, Schneider Electric also design and integrate plant cloud and industrial edge computing solutions that can help businesses regain their productivity momentum. For more on productivity benefits of cloud and industrial edge computing, see their IoT 2020 Business Report.