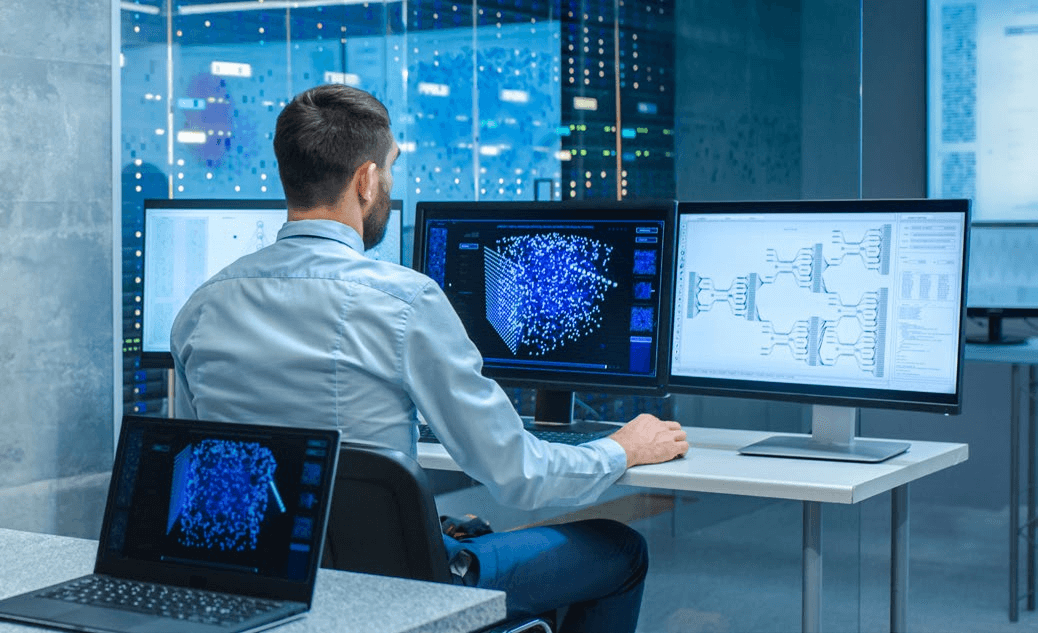

‘Intelligent control systems’ in industrial control and automation refers to systems that use advanced technologies, such as artificial intelligence (AI) and machine learning (ML), to enhance the performance, efficiency, and adaptability of industrial processes.

Key features and benefits of industrial intelligent control systems

- Learning and Adaptation: These systems can learn from historical data and adapt to changing conditions in real-time. This allows for more precise control and optimisation of processes.

- Predictive Maintenance: By analysing data from sensors and other inputs, intelligent control systems can predict equipment failures before they occur, reducing downtime and maintenance costs.

- Enhanced Decision-Making: They can process vast amounts of data to make informed decisions quickly, improving the overall efficiency and productivity of industrial operations.

- Integration with IoT: Intelligent control systems often integrate with the Internet of Things (IoT), allowing for seamless communication between devices and systems, further enhancing automation and control.

- Improved Safety and Security: These systems can monitor and respond to potential safety hazards and security threats in real-time, ensuring a safer working environment.

The Future of Manufacturing

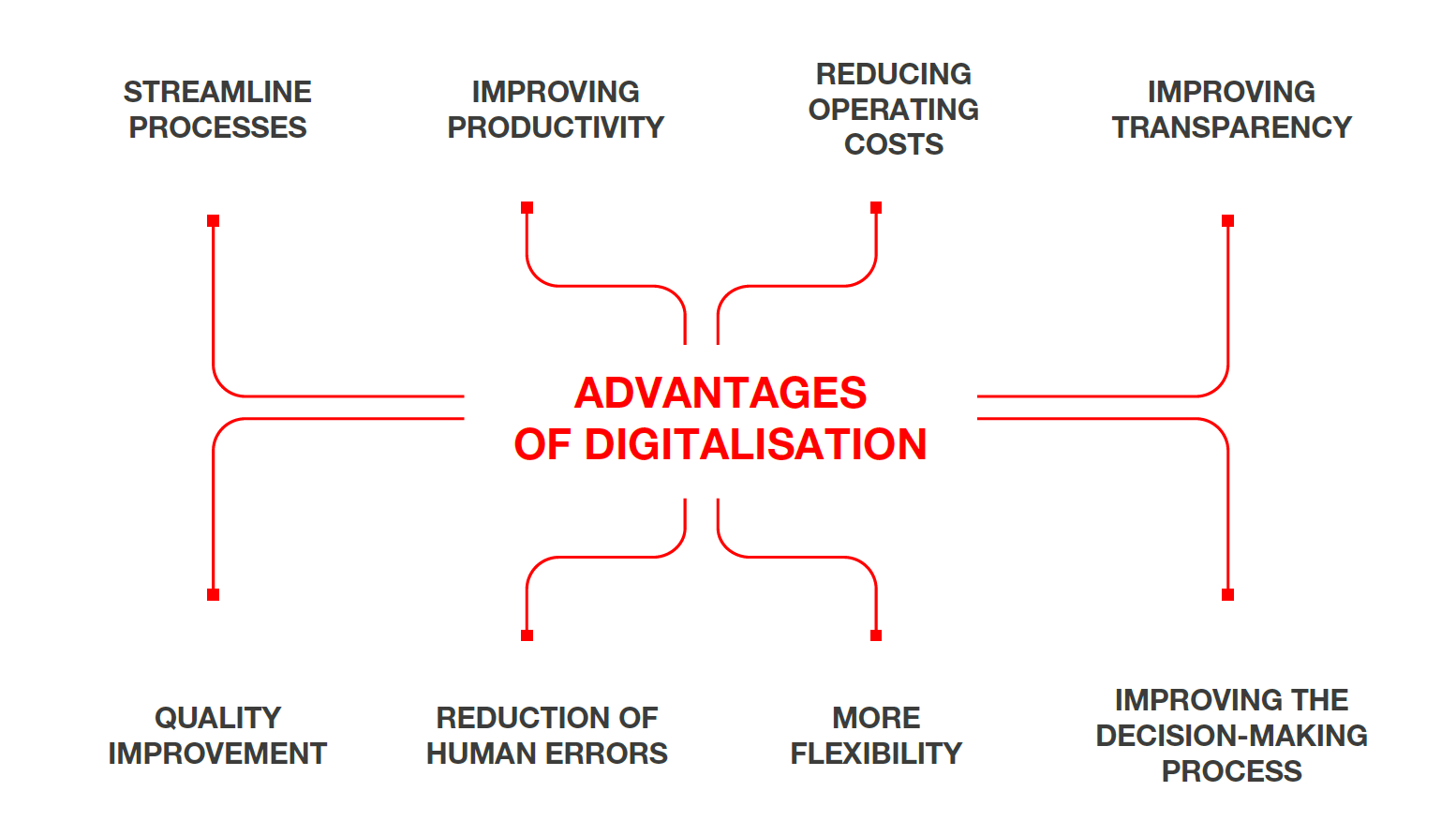

- The importance of digitalisation-enabled solutions

- The advantages of digitalisation

- The capabilities of offered by intelligent control systems

- Smart manufacturing kaizen level

- Intelligence at the component level

- Machine-level intelligence

- Advanced analytics on the edge

- The optimum solution for data analysis and visualisation

- A new dimension of data analytics – Bottom-up

Don’t miss this opportunity to stay ahead in the industry. Check out this white paper now and take the first step towards revolutionising your manufacturing processes.

Don’t miss this opportunity to stay ahead in the industry. Check out this white paper now and take the first step towards revolutionising your manufacturing processes.

Access the ‘Intelligent Control Systems: The Future of Manufacturing’ white paper by clicking on the thumbnail opposite.

Access the ‘Intelligent Control Systems: The Future of Manufacturing’ white paper by clicking on the thumbnail opposite.

Keen to learn more about intelligent control systems?

Don’t forget to join Mitsubishi Electric live for their Building Better Machines webinar on 19th September 2024 at 11:00 AM (UTC+02).

You can register here >>

BPX are proud Innovation Partners of Mitsubishi Electric, and since 1989, the largest independent technical distributor of Mitsubishi Electric automation equipment in the UK. Should you wish to know more about a specific application or technology within intelligent control systems with a member of our Application Support Team and a Mitsubishi Electric specialist, please don’t hesitate to submit our contact form below, and we’ll be in back in touch at the earliest opportunity.

[ivory-search id=”5202″ title=”Custom Search Form”]