Most of us are familiar with passive infrared (PIR) detectors for sensing movement. Popular uses include security applications and controlling lighting in commercial premises to conserve energy. But radar sensors [also known as microwave, RF or Doppler sensing] are growing in popularity as it does not rely on a heat signature.

As with most electronics, radar sensors benefited from reductions in both size and cost. Add to this the practical advantages of radar compared with the limitations of PIR, and it is easy to see why their popularity is increasing. For example, single and multiple detection zones are simple to programme. Moreover, radar can detect the direction of travel, speed and distance of the target.

The performance of PIR and radar sensors varies by manufacturer and specification, but in general, they operate similarly. Furthermore, as the capability of radar sensors advances, more information becomes available to the safety system designer.

PIR Sensors

PIR sensors use a combination of body heat and movement to detect the presence of a target moving across the detection zone. They are dependable and inexpensive, but also have a limited range and need to be visible. Because they cannot detect the direction of travel, they are sometimes operated without cause, for example, with shop doors.

How do Radar Sensors work?

Radar sensors detect motion by sending out microwaves signals and measuring the returned signal bouncing off-targets in the detection zone. This sets its normal baseline state. On detecting movement in the detection zone, disruption of the microwaves will cause the alarm to trigger. They are suitable for larger detection zones and detect the direction of travel to help prevent misoperation. They are also better able to detect or ignore the size of the target where appropriate. To a lesser extent, they also operate through the glass.

PIR vs Radar

Using PIR is a cheaper solution and is simple to install and operate for defined presence patterns. Radar on the other hand offers more complex imaging and accommodates complex algorithms. For some applications, using a combination of the two provides the optimal outcome.

Radar is more dependable at extremes of temperatures and also unaffected by smoke, fog, falling snow or dirt. Detectors are also small and inconspicuous and suitable for hiding behind non-metallic materials. Most PIR detectors have a range of up to ten metres, whereas radar may operate at a range of fifty metres.

Industrial Applications

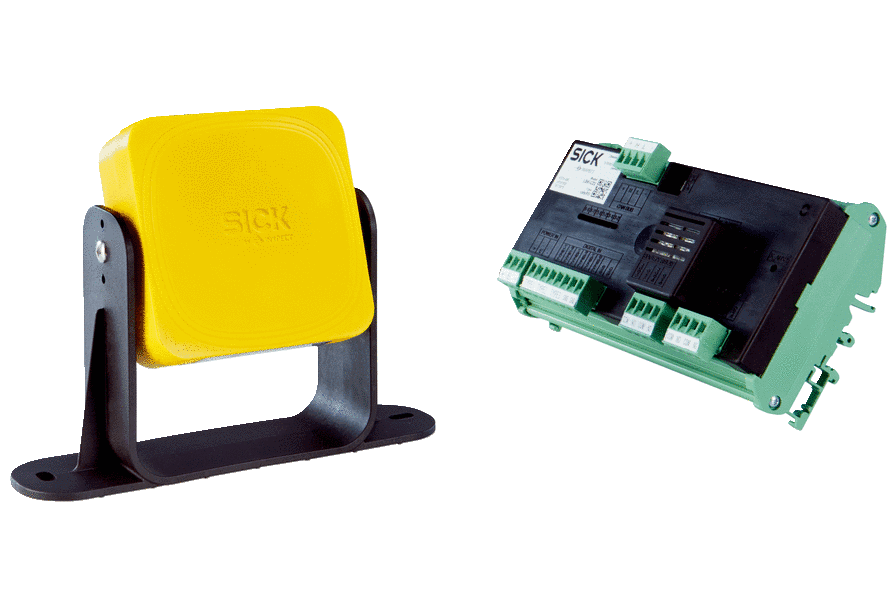

With the increased use of robots and automated machines, radar sensors offer extended protection to hazardous areas. For example, the SICK safeRS offers a programmable three-dimensional protective field to protect personnel in high-performance machine areas. safeRS is a modular system for protection tasks up to Performance Level d and SIL 2 per ISO 13849-1 and IEC 62061.

safeRS

Consisting of an evaluation unit and up to six sensors, it enables switchover to a protected mode as soon as a person enters the protected area. safeRS offers high resistance to dirt, dust clouds, wood chips, plastic particles and sparks. Insensitivity to ambient light such as solar radiation or infrared waves ensures reliable operation in tough ambient conditions. Its rugged sensor housing makes it simple to install and commission.

Go here for a safeRS tutorial on how simple it is to set up and configure the Safe Radar System